- DESIGNING. CONSTRUCTION. COMPUTER AIDED PROJECTS

- MACHINES FOR ROADWAY DRIVAGE

Roadheaders; roadheading systems.

- ROADWAY SUPPORTS

Support: steel; mesh; bolting; face-ends; temporary; individual props; mechanized support; bolters; equipment for support installation.

- LOADING MACHINES

Loaders: gripping; bucket-side-discharge; for ripping the floor and overhead; arm; scraper.

- CUTTING MACHINES

Shearers; ploughs; saws for coal; hammers; cutters.

- CUTTING METHODS. CUTTING TOOLS

Cuttability of coal and rocks; cutting: with roof fall, with stowing; with blasting; forcing-in water; water jet cutting; cutting tools; bits; drill bits; drilling teeth.

- LONGWALL SUPPORT

Mechanized roof support: chock, shield; chock-and-shield; frame; hanging; for stowing; for sandy floor; individual support.

- MECHANIZED LONGWALL SYSTEMS. LONGWALL. EXPLOITATION

Systems for thick, medium, thin and steep seams. Shearer longwall systems; plough longwall systems.

- MACHINES FOR ROOM AND PILLAR EXPLOITATION

- MACHINES AND EQUIPMENT FOR RUN-OF-MINE TRANSPORTATION FROM EXPLOITATING FACES

Scraper buckets; conveyors: scraper; belt; loading elevators; belt conveyors flights; other conveyors; crushing equipment; dischargers equipment; loading spots; surge tanks; pushers; loading and unloading equipment; additional equipment for adaption of belt conveyors for men riding.

- WHEELED TRANSPORTATION

Rail-mounted mine cars-universal and special; locomotives; electric traction; self-propelled cars; chain railways; track barriers; track brakes.

- HYDRAULIC AND PNEUMATIC TRANSPORT

Jet pumps; injectors; feeding and collecting devices; pipelines.

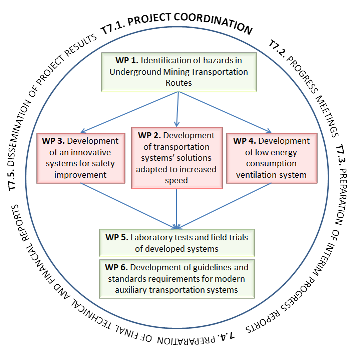

- AUXILIARY MINE TRANSPORT

Underground railways – monorails and floor-mounted; winches; rope-pulling device; pallets; containers; special cars.

- STOWING MACHINES AND EQUIPMENT

Stowing materials; filling: hydraulic, dry, pneumatic – slung; filling pipelines; transport of filling material; stowing machines; stowing dams.

- AUXILIARY MACHINES AND EQUPIMENT FOR AUXILIARY OPERATIONS

Hammers; manual saws; chisels; bolters, shifters; wedges; pushers; disassembly pullers, hoists, horseheads; safety winches; devices fixing machines and equipment; legs; sprags; machines for assembly and disassembly; mobile cranes.

- DRILLING MACHINES AND EQUIPEMNT

Drills; drill rigs; drilling jumbos; sprag pillars; extension arms; manipulators; drill pumps.

- VENTILATION MACHINES AND EQUIPMENT

Ventilation and air-conditioning of mines; fans; ventilation reverse; ventilation pipes; ventilation pipelines; blowers; coding devices.

- DEWATERING OF MINES

Pumps: for central dewatering; face; for heavily contaminated liquids; pump systems.

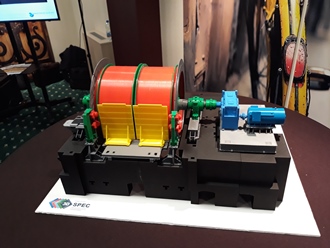

- VERTICAL TRANSPORT

Winding machines; winding equipment; conveyances; winding ropes; suspension gears; rope pulleys; shaft towers; equipment for shaft top and shaft bottom – batchers, scales, shaft sinking equipment.

- MECHANICAL PROCESSING

Crushers; mills; sieves; floatation machines, dust collectors; jigs; concentration tables; picking tables; drivers; air classifiers; centrifuges; drum; hydrocyclone; stream and heavy medium separators.

- HYDRAULIC AND PNEUMATICS

Hydraulic pumps; hydraulic engines; hydraulic cylinders; connectors; manipulators; hydraulic accumulators; glands; valves; seals; hydraulic oils; emulsions; pneumatic drives; compressors; pneumatic engines; dewaterers; oil separators; filters; dividers; fittings.

- ENVIRONEMATAL PROTECTION. USE AND STORAGE OF WASTE. LAND RECLAMATION

- DIESEL DRIVES OF MINING MACHINES

- PRINCIPLES OF MINING MACHINERY AND EQUIPMENT DESIGN

Parts of machines; elements of drives; control; strength control; construction materials; wear of materials; energy consumption.

- WORK SAFETY AND HYGIENE IN THE MINING INDUSTRY. ERGONOMICS

Work Safety and Hygiene; accident rate; protection against noise and vibration; protectors, protecting clothing; lighting of machines; dust control; fire hazards caused by mining machines.

- EXPLOITATION AND RELAIBILITY OF MACHINES AND EQUIPMENT

Reliability theory; reliability systems; developing software of failure-less operation time and of repair time; attestation; life tests; approvals for exploitation; ageing processes; lubrication; friction; wear. Technical diagnostics.

- ELECTRIC DRIVES. AUTOMATION. MECHATRONICS. MEASURING AND CONTROL APPARATUS. EXPLOSION – PROOF EQUIPMENT. ROBOTICS. COMMUNICATION. ENERGY SOURCES

- PLASTICS IN CONSTRUCTION OF MINING MACHINES

- ANTI-CORROSION PROTECTIONS

- REPORT MATERIALS

Reports on business trips abroad; conferences; meetings; fairs and exhibitions; general descriptions of machines and equipment.

- ORGANIZATION AND MANAGEMENT. RESTRUCTURING OF MINING INDUSTRY

Descriptions of plants; technological, economical and organizational progress; unmanned mining; production rates of mines; scientific-and-technical information; forecasting; patents; rationalization; inventiveness; know-how; licenses; work and salaries; finances; personnel.

- CERTIFICATION. ACCREDITATION. STANDARIZATION

Mathematics; Physics; Chemistry; branches of knowledge connected with the mining industry; designing and constructing; history of mining mechanization; tests; data processing; optimization.