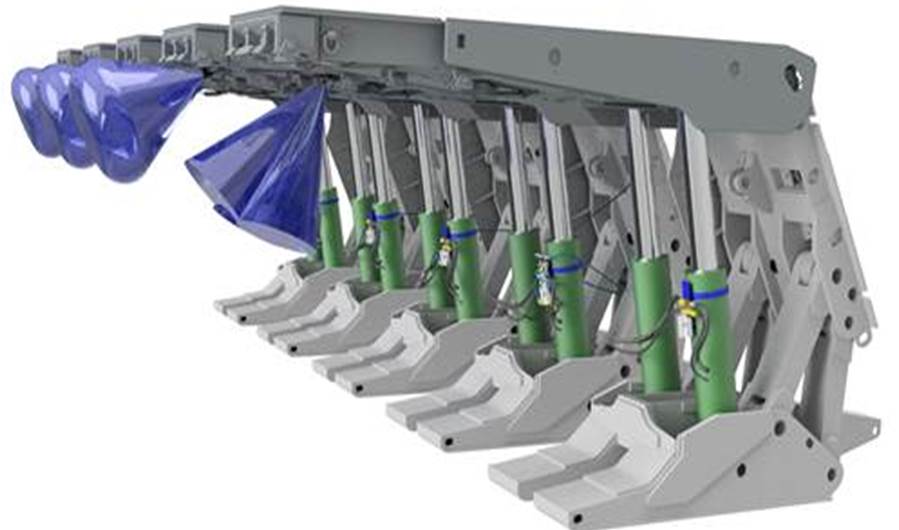

The KOMAG-HR sprinkler system, developed at the KOMAG Institute of Mining Technology in cooperation with the Elektron Innovation and Implementation Company, is used to reduce dust generated into the workings during the mining of coal seams and to locally reduce the concentration of methane released from the rock mass. The system is designed for underground mine workings excavated by longwall technology, causing dust particles. The KOMAG-HR hybrid system solution is equipped with two integrated types of sprinkler subsystems located along the entire longwall workings:

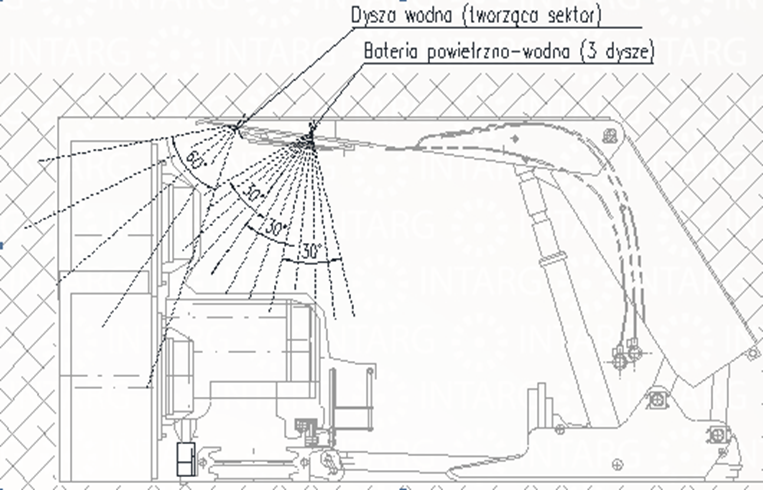

- air-water (several batteries, every tenth section)

- sectoral (water nozzles under each section grouped into sectors).

The sprinkling streams generated by the air-water batteries are directed into the mining space of the shearer, thus reducing the dust carried in the flowing air.

On the other hand, water jets (which are part of the sector sprinkler) are directed toward the side wall, in order to locally reduce the concentration of methane escaping from the face of the wall during mining.

The system uses self-cleaning nozzles to protect against the ingress of contaminants and increase the reliability of operation. The installation and operation of each subsystem is independent and determined by the manner of exploitation. The system was awarded in the Innovative Product & Technology Expo Katowice competition in the Safety Improvement category. The solution is protected by the following patents:

Patent: PL224886 - Method and installation of air and water sprinkling in the longwall workings,

Patent: PL223893 - Self-cleaning two-factor sprinkler nozzle,

Patent: PL221151 - Two-factor sprinkler nozzle.

Inventions filed with the Polish Patent Office:

P.440991 - Method and installation for dust reduction and removal of local accumulations of methane in a longwall workings (authorized ITG KOMAG).