Select a news topic from the list below, then select a news article to read.

Representatives of the Laboratory of Material Engineering and Environment and Research Laboratory of KOMAG Institute took part in the 27th International Fair of Plastics and Rubber Processing PLASTPOL in Kielce. Among other things, these laboratories are involved in testing the safety of use of various types of products, including those intended for children or for contact with food.

PLASTPOL is one of Europe's largest trade fairs related to plastics. Organized by Kielce Fair, the event is not only an exhibition space, conferences and lectures, but also an opportunity to establish business relations.

Nearly 600 companies from 26 different countries participated in this year's edition.

Gold Medal at The 16th International Invention and Innovation Show INTARG 2023 was awarded to HEETII, an innovative electrical power supply system for machines, as well as mobile devices, whose creators are: Krzysztof Stankiewicz, Bartosz Polnik, Marcin Skóra, Marcin Kasprzak, Zbigniew Kaczmarczyk, Mirosław Wójcik, Dariusz Szymczak and Zbigniew Szkopek.

For more details, please visit the website of the Fair Organizers.

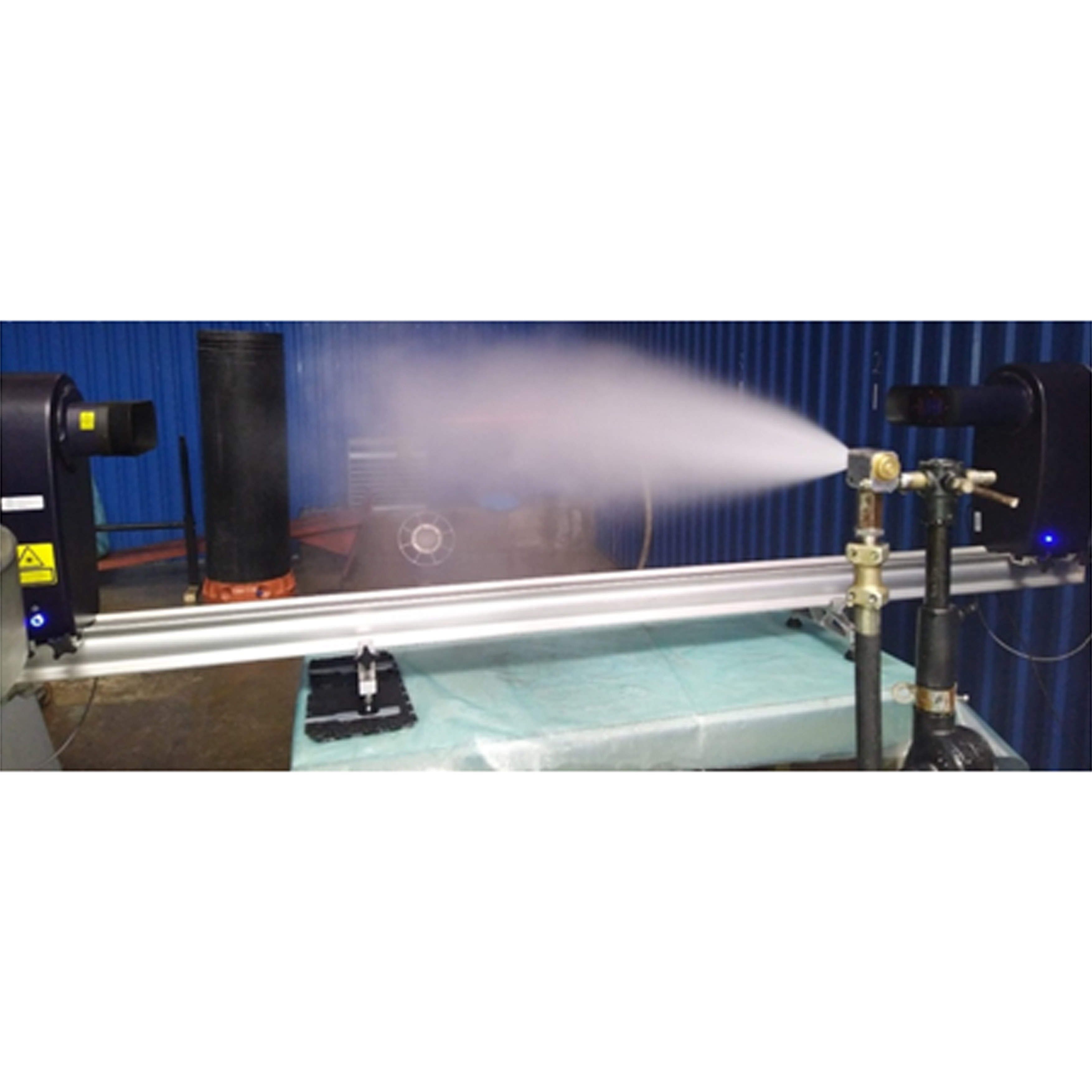

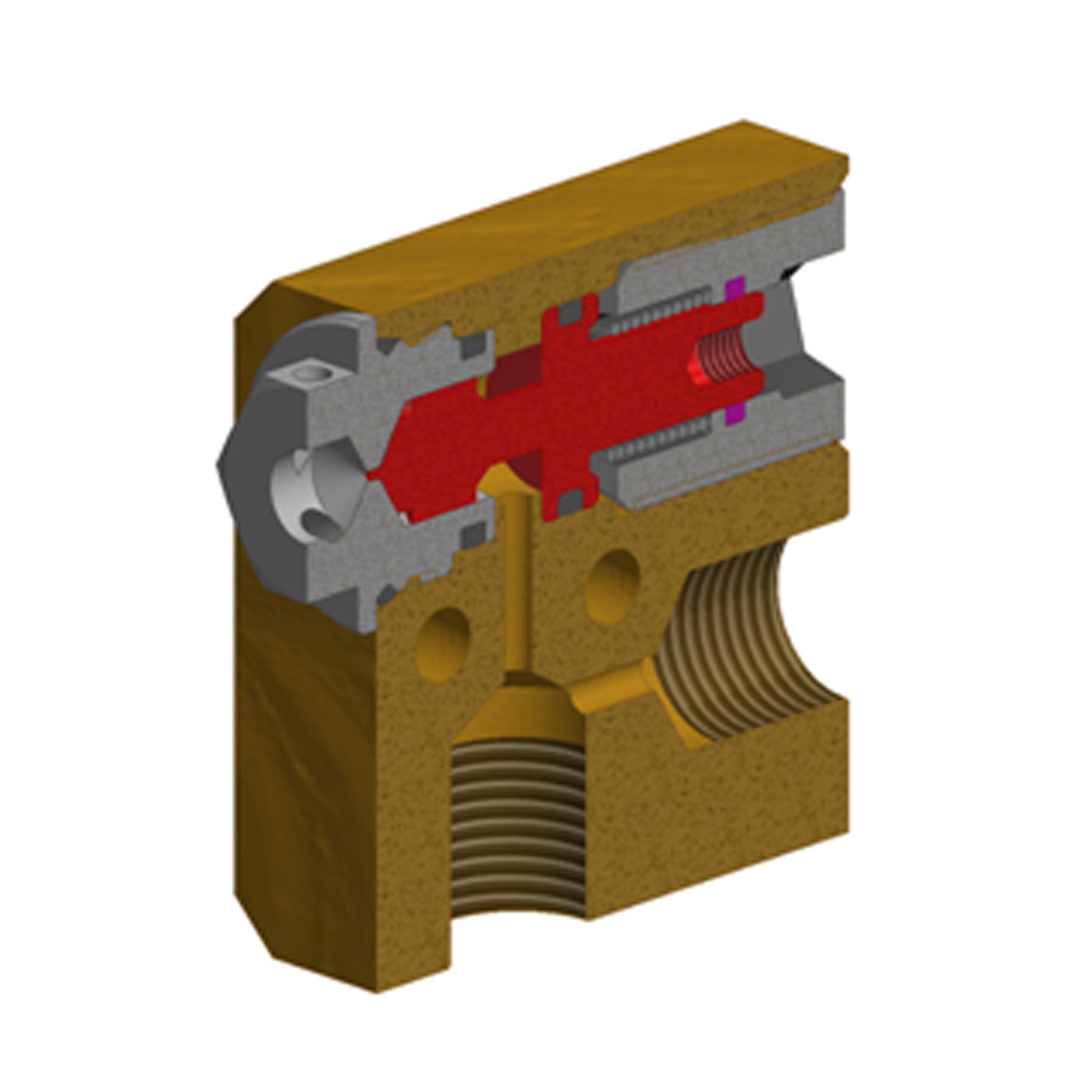

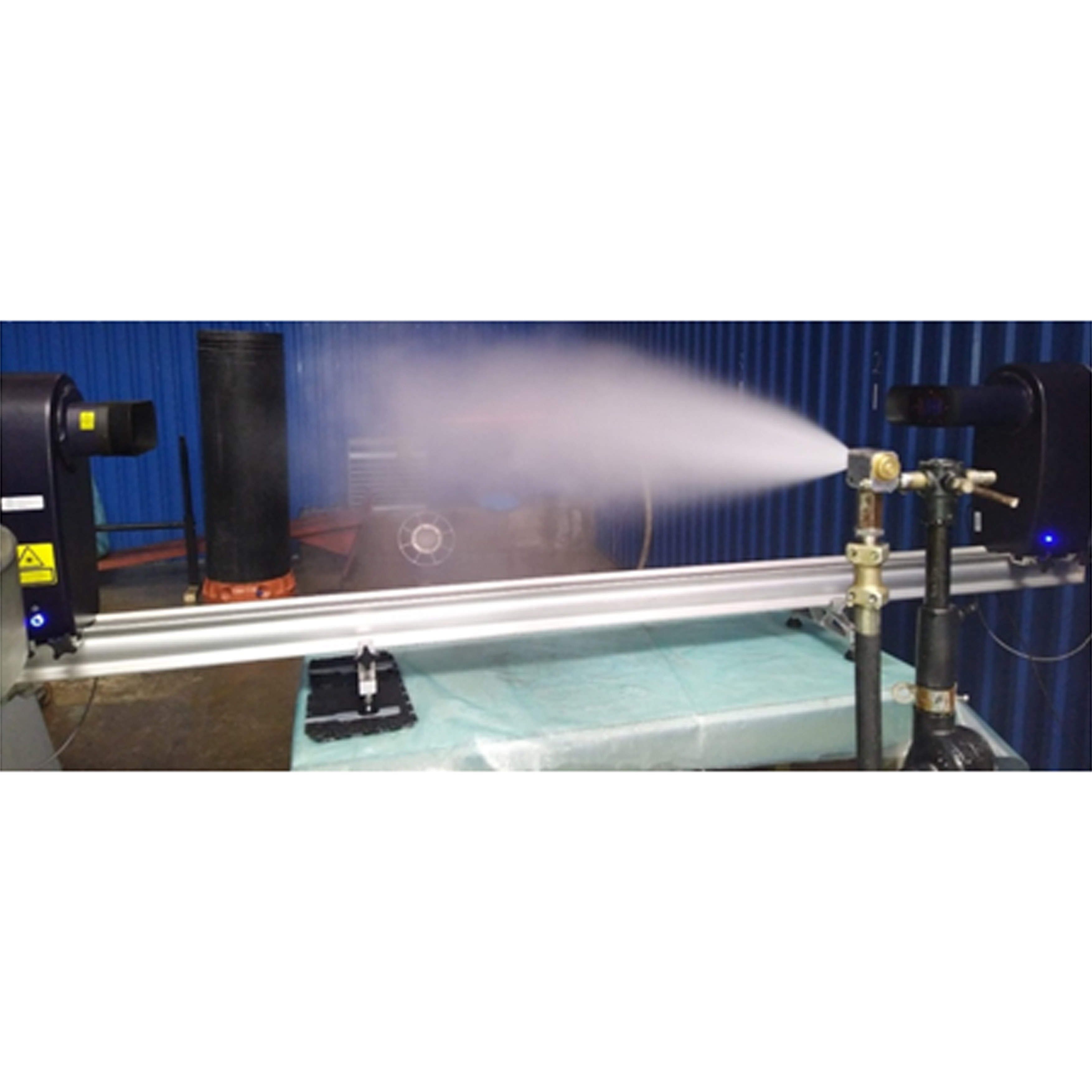

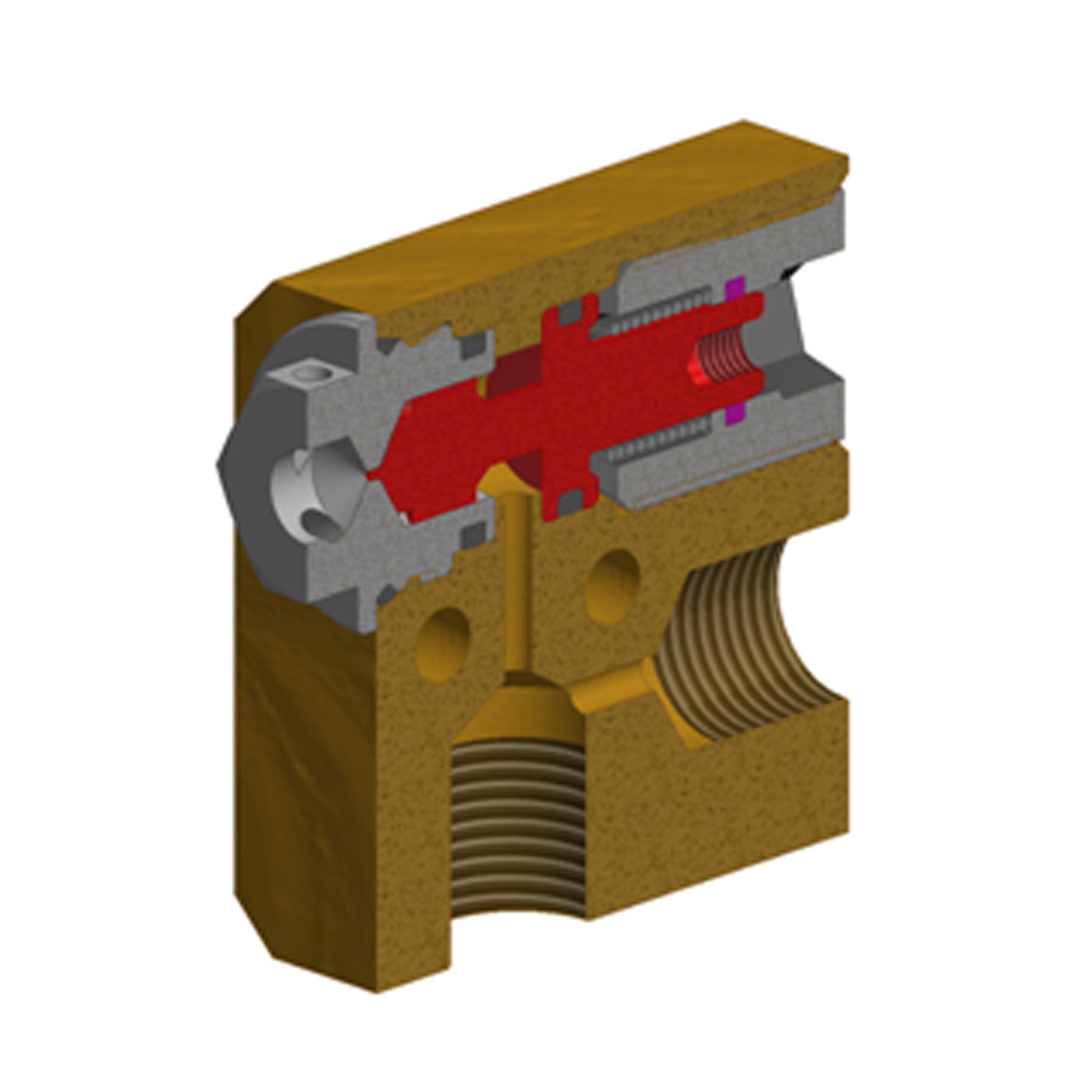

We are happy to announce that the project by KOMAG Institute in cooperation with Elektron Company has been awarded the Silver Medal during this year's International Invention and Innovation Show INTARG, which took place on 24-25 May in Katowice. The KMG-EWS SELF-CLEANING WATER NOZZLE was created to reduce dust and prevent methane ignitions in mines. The nozzle is equipped with a self-cleaning system, which prevents clogging and is therefore safer than the solutions used so far. Other advantages include low water consumption, as well as high water droplet fragmentation. The creators of the project are: Director of ITG KOMAG Dariusz Prostański, Dominik Bałaga, Marek Kalita, Michał Siegmund, Michał Bidas, Andrzej Urbanek and Arkadiusz Waloszczyk. Congratulations!

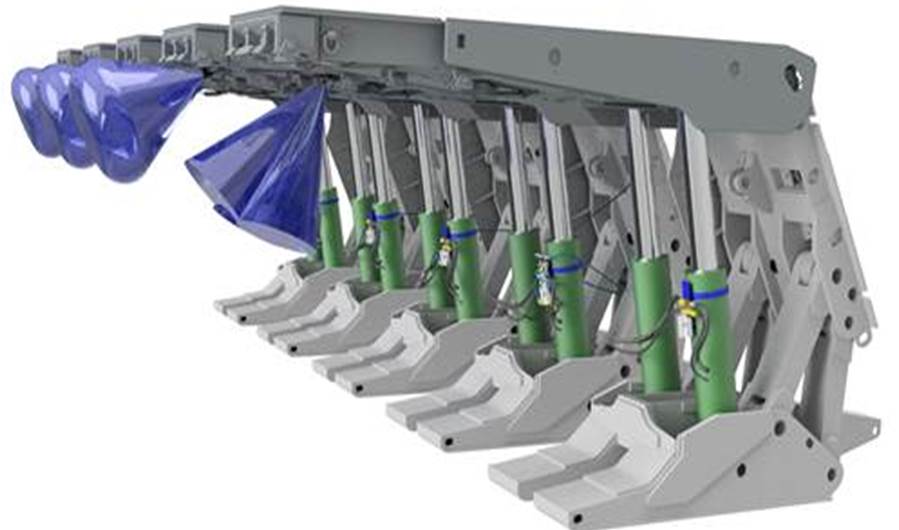

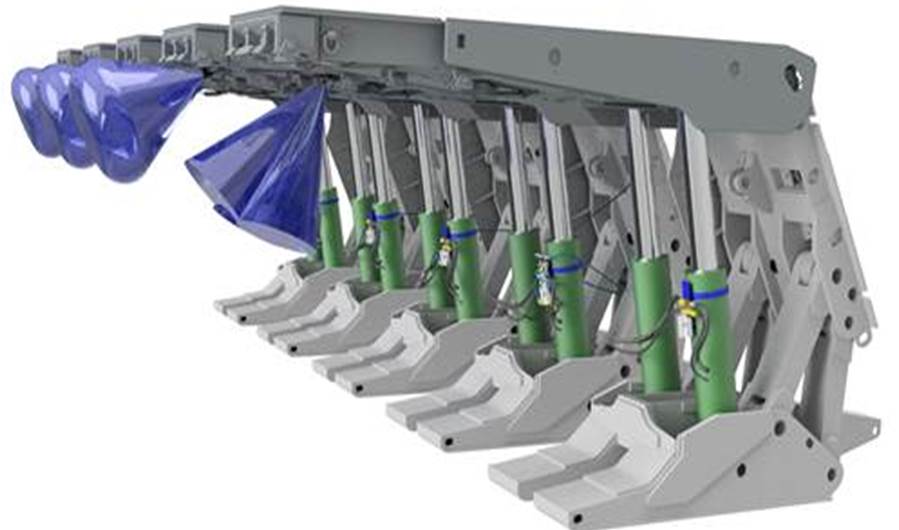

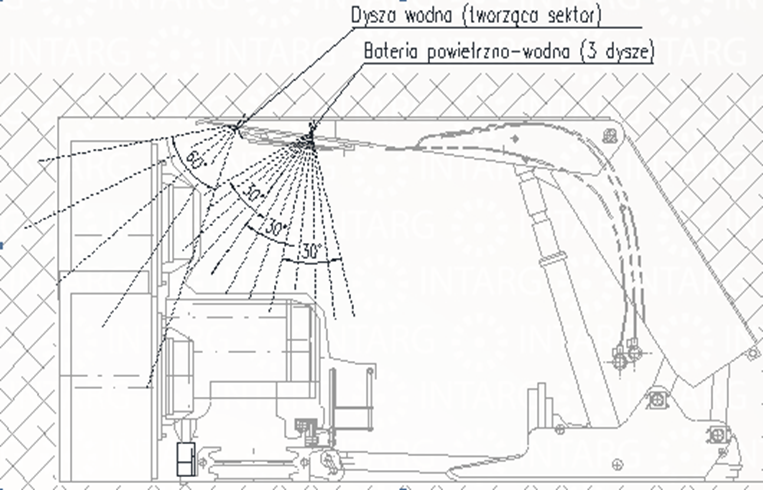

The KOMAG-HR sprinkler system, developed at the KOMAG Institute of Mining Technology in cooperation with the Elektron Innovation and Implementation Company, is used to reduce dust generated into the workings during the mining of coal seams and to locally reduce the concentration of methane released from the rock mass. The system is designed for underground mine workings excavated by longwall technology, causing dust particles. The KOMAG-HR hybrid system solution is equipped with two integrated types of sprinkler subsystems located along the entire longwall workings:

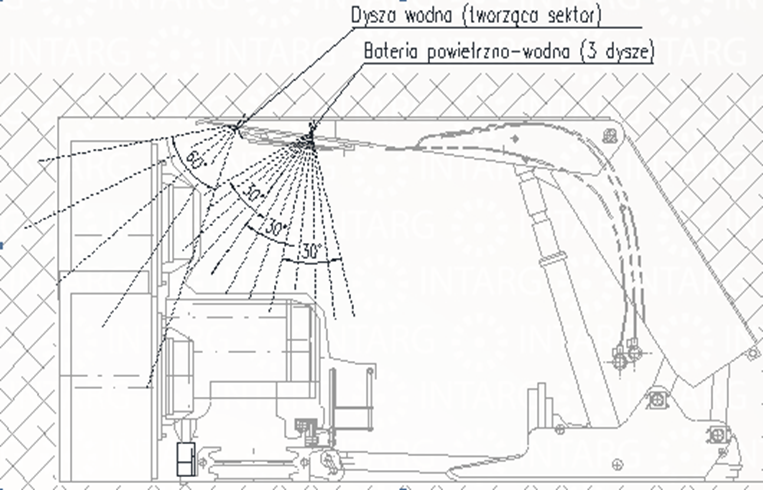

- air-water (several batteries, every tenth section)

- sectoral (water nozzles under each section grouped into sectors).

The sprinkling streams generated by the air-water batteries are directed into the mining space of the shearer, thus reducing the dust carried in the flowing air.

On the other hand, water jets (which are part of the sector sprinkler) are directed toward the side wall, in order to locally reduce the concentration of methane escaping from the face of the wall during mining.

The system uses self-cleaning nozzles to protect against the ingress of contaminants and increase the reliability of operation. The installation and operation of each subsystem is independent and determined by the manner of exploitation. The system was awarded in the Innovative Product & Technology Expo Katowice competition in the Safety Improvement category. The solution is protected by the following patents:

Patent: PL224886 - Method and installation of air and water sprinkling in the longwall workings,

Patent: PL223893 - Self-cleaning two-factor sprinkler nozzle,

Patent: PL221151 - Two-factor sprinkler nozzle.

Inventions filed with the Polish Patent Office:

P.440991 - Method and installation for dust reduction and removal of local accumulations of methane in a longwall workings (authorized ITG KOMAG).

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych