Broad, international relations and an interdisciplinary collaboration with foreign scientific and research institutes, technical universities, companies and enterprises, activities aiming at an integration with the European Research Area, extending traditional forms and scopes of collaboration, a generation of new projects, in particular within the scope of the priority fields of activity, specified by the European Union in the Framework Programmes and also a participation in international organizations, collaborative networks and technology platforms are measures of KOMAG's successes.

KOMAG takes an active part in the activities of three European Networks of Excellence:

-

AMAS NoE – Advanced Materials and Structures

(Polish Academy of Sciences)

-

ENVITECH-Net – Environmental Technologies

(Institute for Ecology of Industrial Areas)

-

EST – Environmentally Sustainable Transport

VITO Flemish Institute for Technological Research).

A European Commission's nomination of KOMAG to the role of he Centre of Excellence within the 5th Framework Programme in the scope of advanced, safe and reliable mechanical systems confirms a high, scientific position of KOMAG in the European Research Area. The experience, gained during a realization of that project and new partners, representing the leading research institutes in Europe, have had a strong impact on the subject matter and scope of scientific and research projects, developed by KOMAG and connected, among others, with the research on he relationship: man-machine-environment and a development of new generation mechanical systems.

|

The main objective of activities, undertaken by KOMAG and in particular connected with a realization of the basic, strategic tasks, is an integration with the European Research Area in the scope of designing, testing and production of machines as well as an increase in the competitiveness of Polish solutions in the European market. |

The international activity of the KOMAG Institute is dominated by the problems resulting from its general strategy, according to which a participation in the European Union research programmes is one of top priorities. Activities oriented onto broadening traditional subjects and forms of collaboration and a realization of new research programmes are undertaken on a large scale. That in particular refers to the following domains: health, power-engineering, mechatronics, new materials and technologies as well as ecology.

A collaboration within the Research Fund for Coal and Steel develops in a very interesting way. Since 2008 KOMAG has been taking an active part in its activities, participating in the actions co-ordinated by the EURACOAL European Association for Coal and Lignite and also by the EUROMINES - European Mineral Resources RTD Council.

European research projects in which the KOMAG Institute actively participates:

Erasmus+ Programme:

|

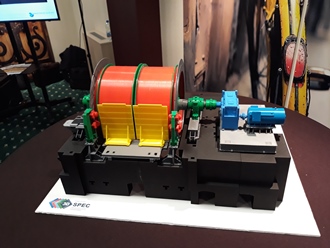

Specialist in 3D printing - specialized training in application of 3D printing and practical use of acquired knowledge. |

|

|

The coordinator: KOMAG Institute of Mining Technology The consortium members:

The implementation period: September 2016 – August 2019 The goal of the project: 3DSPEC Specialist in 3D printing - specialized training in application of 3D printing and practical use of acquired knowledge. The project’s goal is to provide a comprehensive training in use of 3D printing technology in the following areas: education, design, healthcare, SMEs’ operation. There are two main elements of the training: i) online 3DSPEC course which provides solid theory regarding 3D prinitng as well as application examples and instructions to follow, ii) Internet platform for ordering 3D printing on 3D printers available in 3D Printing Centre (3D printers located at project partners’ facilities) via which trainees will have opportunity to make sample printouts and this way practice what they’ve learned. |

|

|

|

|

Research Fund for Coal and Steel:

|

Productivity and safety of shield support. |

|

The coordinator: KOMAG Institute of Mining Technology The consortium members:

The implementation period: July 2017 – June 2020 The goal of the project: Deeper and deeper mining of hard coal seams causes that mining crew and equipment are exposed to greater natural hazards. At present progress in the field of automation of mechanized longwall systems does not include monitoring of roof behaviour and preventing against disadvantageous phenomena associated with roof behaviour, such as roof falls to the longwall face or lack of roof fall beyond the shield support leading to local dynamic loading to the working. It is assumed that by monitoring both shield support behaviour (leg pressures, geometry and tip to face distance) and geotechnical conditions in longwall in real time, warnings about significant improper shield support behaviour and formation of roof instabilities, such as roof cavities/falls or shield closure, will be given several hours in advance. This advance warning allows miners to take preventive action which in turn can reduce longwall downtime and exposure to hazards. Such on-line solutions are not used at present. Development of Shield Support Monitoring System (SSMS), which will enable monitoring of roof condition in real time, through monitoring the parameters of shield support, as well as development of Longwall Mining Conditions Prediction System (LMCPS) for prediction of roof falls hazards and generation of information about indispensable corrective measures, is the project objective. LMCPS will be developed on the basis of the geomechanical models and tests of SSMS in real conditions. Geomechanical models are developed from three sources. The physical models, the numerical models (to date with qualitative aspects) and the underground measurement data, which hitherto should not be at variance with the developed theory. The suggested research work will be undertaken by a well-balanced, interdisciplinary consortium of underground control system developers and manufacturers, shield support designers, mining institutes and mining company complemented by assistance of one University. |

|

|

Information Driven Incident RESponse. |

|

|

The coordinator: Uniwersytet Exeter United Kingdom The consortium members:

The implementation period: July 2017 – June 2020 The goal of the project: It is addresses the crucial issue of rapidly acquiring and providing information which is a key necessity in the effective response to a serious mining incident. As such, it will facilitate Information Driven Incident Response. The primary objective is to enable information to be gathered and exchanged, without reliance on a mine's fixed power or communication networks, while planning, and during the execution of, a response to an incident that could jeopardize the lives of personnel and the future operation and profitability of the mine. Research will be conducted into two resilient and novel methods of communications that are independent of fixed networks, one operating through rock, the other using a readily deployable cable. These will be key enablers of other technologies developed in INDIRES and will also provide a vehicle for person-to-person voice or textual exchanges for rescue personnel, mine management and trapped miners. Environmental sensors will be developed that are resilient to incidents such as explosions or fires and which can provide immediate access to environmental data in the aftermath of the accident. Small unmanned vehicles – employing a flying, climbing and/or crawling concepts – will be developed for very early reconnaissance of areas affected by an incident before deploying personnel. These vehicles will carry environmental sensors plus thermal imaging cameras for detecting life signs. Highly efficient drilling technology using a torsional torque converter will be researched and props produced using new composite materials. These will provide a self-contained, lightweight solution for drilling exploratory tunnels to facilitate communication with affected areas and access to robotic vehicles, and could potentially allow trapped minders to be released. Simulations will be used to augment live data with information on environmental conditions and probable escape routes. |

|

|

|

|

|

Reducing risks from Occupational exposure to Coal Dust. |

|

|

The coordinator: UNEXE - Uniwersytet w Exeter – United Kingdom The consortium members:

The implementation period: July 2017 – June 2020 The goal of the project: Despite international efforts to limit worker exposure, coal mine dusts continue to impact the health of thousands of miners across Europe. Modern, practicable assessment tools and devices are urgently needed to improve risk models, control dusts and protect workers, particularly from the fine fraction (PM2.5) which is increasingly implicated in human disease. These issues will be addressed through 5 integrated work packages by a world-leading interdisciplinary consortium of 10 institutions from 5 European countries. Global dissemination of developed protocols and training modules, and production of new monitoring and suppression devices will greatly reduce incidences of coal mining-related disease. |

|

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych