In the scope of accredited material tests KOMAG Laboratory of Material Engineering and Environment performs among others:

|

|

The above-mentioned scope of tests is used by the Laboratory for:

- a verification of products' quality for conformity with tender documentation, steel attests, standards and other technical requirements,

- an evaluation of technical condition and wear degree of machine elements and devices within periodical and interventional surveys as well as allowing for exploitation approvals.

|

|

|

|

Analysis of chemical composition by means inductively coupled plasma atomic emission spectrometry and infrared spectroscopy |

|

|

|

|

|

Roughness measurement by means of profile method |

Thickness measurement by means of magnetic method and eddy currents |

|

|

|

|

Thickness measurement by means of (UT) ultrasonic method |

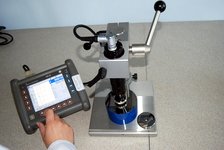

Hardness measurement by means acoustic resistance |

|

|

|

|

Testing corrosion resistance in the salt mist |

|

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych