Roadway Systems

KOMAG develops concepts, designs and technical documentation of the following roadway machines and equipment

- roadheaders,

- side-discharge loaders,

- drilling jumbos,

- platforms for assembly of roadway supports,

- protecting structures for operators stands,

- diesel drives for underground applications,

- diesel and electric locomotives for underground mine railway,

- diesel narrow-gauge locomotives,

- suspended monorails,

- transportation-and-manoeuvring battery drivetrains,

- mine cars and others,

- railway junctions,

- underground and surface drill rigs,

- rotary-percussive drills,

- small mechanization equipment: hoists and winches with different drives,

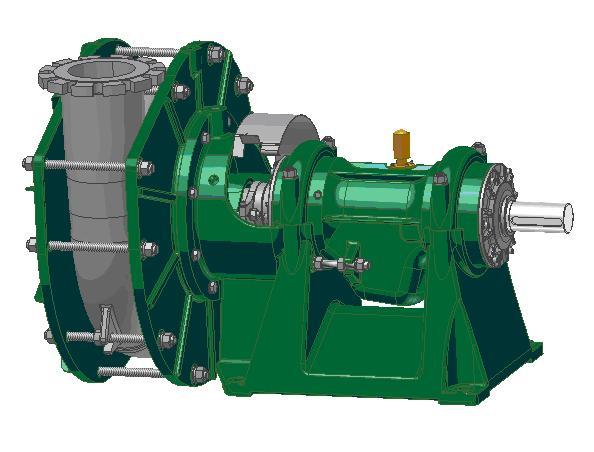

- hydraulic systems for roadway machines of different types,

- hydraulic power packs,

- water filters,

- spraying systems for roadheaders and longwall shearers,

- air-and-water curtains for transferring points and roadways,

- spraying nozzles,

- diesel drive systems.

Solutions for other branches of industry:

- engineering-and-geological drill rigs,

- water curtains for open-pit mining industry and processing plants,

- protecting structures for operators of construction machines,

- hydraulic drive systems.

Hydraulics

We offer development of concepts, designs and technical documentation of the following machines and equipment:

- underground and surface drilling jumbos,

- rotary and percussive drills,

- small mechanization devices: drills, screwdrivers, saws with hydraulic and pneumatic drive,

- hydraulic power packs with electric and hydraulic drive,

- filters for water and oil-water emulsions ,

- devices controlling flow of water,

- auxiliary equipment for cooling systems,

- emulsion plunger pump,

and the hydraulic systems for different types of machines including the following ones:

- roadheaders,

- longwall shearers,

- side discharge loaders,

- drilling jumbos,

- locomotives and haulers used on the surface and mine undergrounds,

- suspended monorails.

We realize the research projects associated with hydraulic supply systems.

Longwall Shearers

KOMAG develops concepts, design projects and technical documentations of longwall shearers and their assemblies:

- shearer ranging arms,

- shearer haulage units,

- flame-proof casings for electric equipment,

- high-pressure hydraulic installations,

- water-spraying systems for longwall shearers,

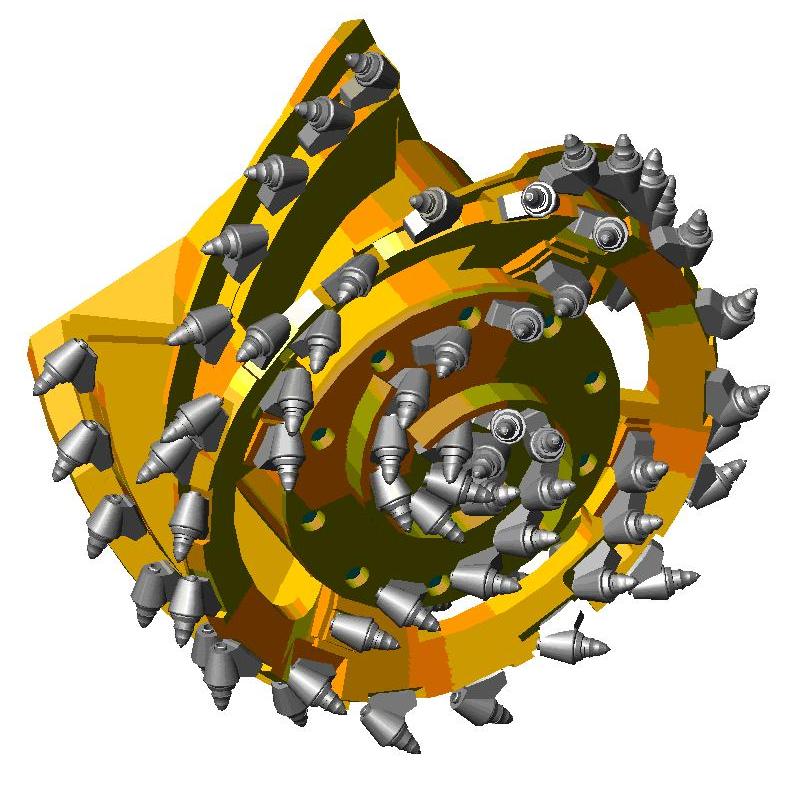

- cutting drums of longwall shearers.

KOMAG develops concepts, design projects and technical documentation of the following equipment:

- special gears for driving conveyors and rail-mounted vehicles,

- flame-proof casings for electric equipment of rail-mounted vehicles,

- small-size drilling rigs,

- equipment for shaft sinking.

Horizontal Transport

R&D projects as regards machines and equipment for wheel, conveyor and rail transportation as well as designs for technology and machinery industry for materials displacement and transportation systems are realized at the Division of Horizontal Transportation.

We also realize projects for modernization of operating machines and equipment as well as designs of additional equipment for the existing machines.

We design the following machines and equipment:

- Belt conveyors and flight-bar conveyors.

- Self-propelled platforms, locomotives as well as electric and diesel drivetrains.

- Bunkers and equipment for storage of loose materials.

- Gravitational chutes and feed stream mechanical dividers.

- Pumps for hydro-transportation and for water.

- Cutter heads of mining machines (e.g. shearers, dredger cutters).

- Lifting machines and mining-and-transportation machines.

- Advanced drive systems.

Designs and documentations as well as modelling of production systems are realized with use of state-of-the-art information technologies and state-of-the-art CAD-3D designing methods.

We develop and provide the following:

- Calculations of continuous transportation equipment.

- Services as regards technical consultancy on horizontal transportation and drive systems.

Contact:

Marek Kalita, Ph.D. Eng.

Manager of the Division of Machines and Equipments

phone: +48 32 2374662

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych