Activity of the Division of Applied Vibroacoustics focuses on the two following subjects:

- research,

- designing of buildings, objects and equipment.

In the research area we offer:

- acoustic analyses, ecological audits as regards acoustic impact,

- analyses of vibrations,

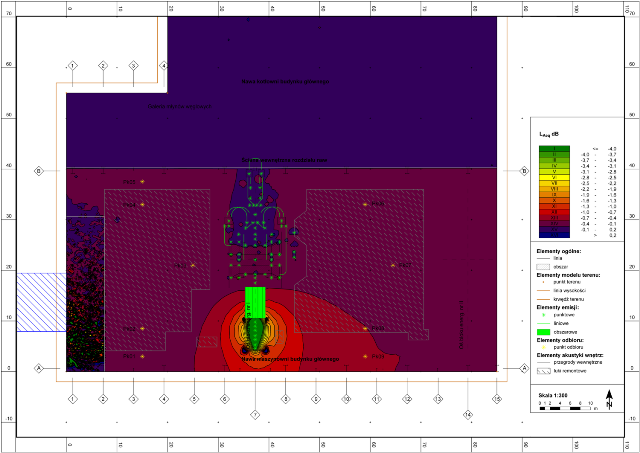

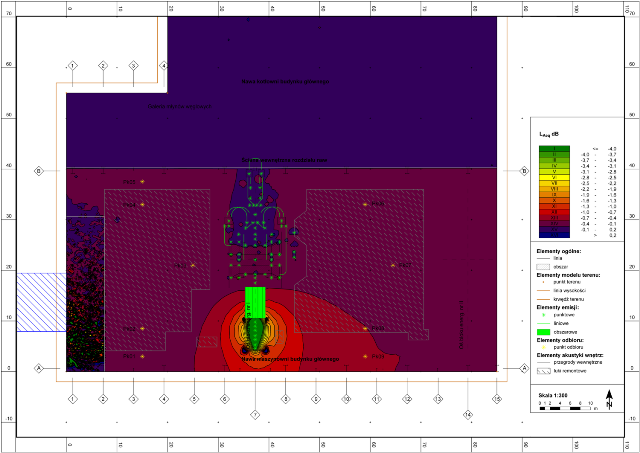

- numerical models of land and GIS technologies,

- modelling of acoustic field in the environment and closed spaces (with determination of impact range and identification of sound sources),

- concepts for reduction of sound emission and mechanical vibrations,

- forecasting of changes in acoustic climate,

- acoustic maps and programmes for protection of environment against noise,

- vibroacoustic diagnostics as well as assessments of exposure of building/engineering objects to mechanical vibrations.

In the designing area we offer:

- functional-and-spatial programmes,

- designs as regards control of vibroacoustics hazards, including:

- acoustic screens,

- sound absorbing-and-isolating shields and casings,

- silencers,

- sound absorbing-and-isolating and lector cabins,

- vibroisolation of objects, machines and equipment,

- designs as regards foundation of machines,

- designs as wellas design-and-construction projects,

- cost calculations and construction take-offs,

- scheduling of construction work,

- supervision over the realization of investments.

We also realize trainings and promotional activity as regards control of noise and vibrations emission.

Exemplary projects and selected design solutions realized in Poland:

Field of action: acoustic screens in the environment - noise-absorbing screens

Project name: Acoustic screen at the railway siding

Place of the first implementation: Grupa Tauron PKW S.A. ZG "Sobieski"

Field of action: acoustic screens in the environment - mixed, absorbing and reflecting screens

Field of action: acoustic screens in the environment - mixed, absorbing and reflecting screens

Project name: Acoustic screen at road 307

Place of the first implementation: Buk, road 307 Poznań-Buk-Opalenica

Field of action: acoustic screens in the environment - reflecting screens

Field of action: acoustic screens in the environment - reflecting screens

Project name: Acoustic screen at Wiadukt Street in Skierniewice

Place of the first implementation: UM Skierniewice

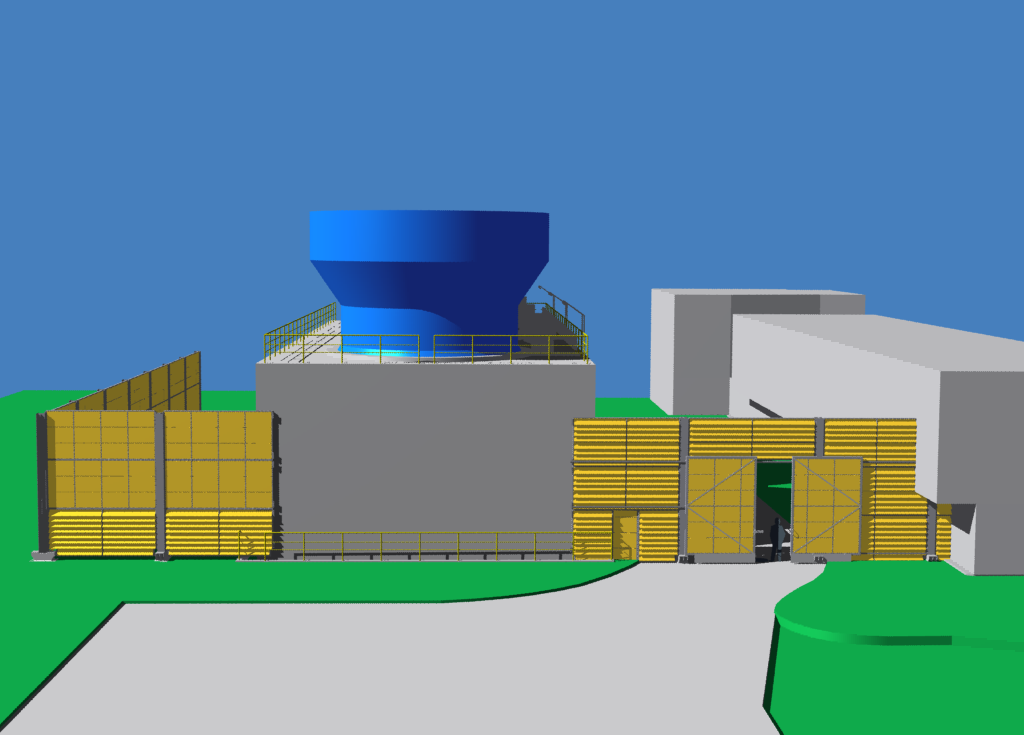

Field of action: acoustic screen with shutter panels

Field of action: acoustic screen with shutter panels

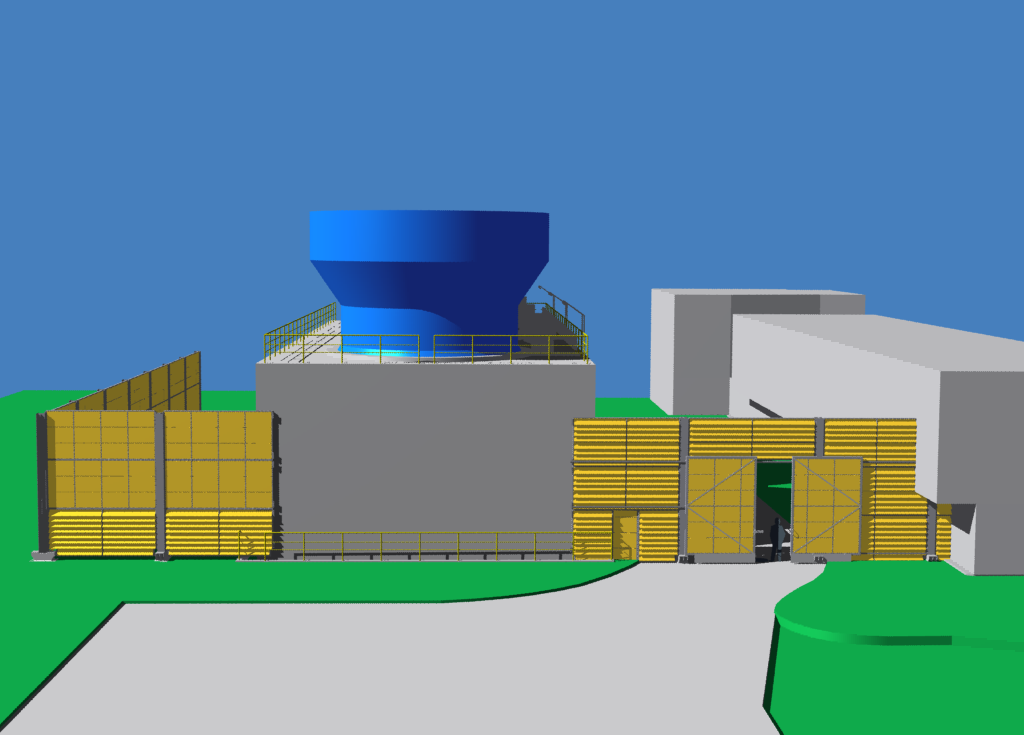

Project name: Silencing the cooler of TZ4 turbine

Place of the first implementation: EC Białystok S.A.

Field of action: acoustic screens in closed spaces

Field of action: acoustic screens in closed spaces

Project name: Acoustic screen in the area of stands for grinding in construction room

Place of the first implementation: Urządzenia i Konstrukjce S.A.

Field of action: silencers

Field of action: silencers

Project name: Acoustically low-emission ventilation system for the strategic objects

Place of the first implementation: KW S.A. Oddział KWK "Bielszowice"

Field of action: silencers

Field of action: silencers

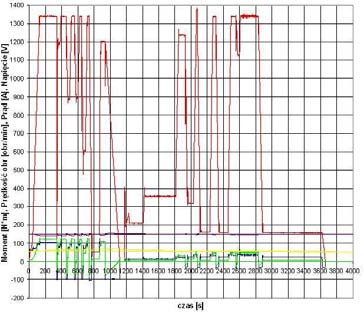

Project name: Silencer for WPWS-160 fan

Place of the first implementation: KW S.A. Division KWK "Jankowice"

Field of action: silencers

Field of action: silencers

Project name: Silencer for WLE mine fans

Place of the first implementation: KW S.A.

Field of action: silencers

Field of action: silencers

Project name: Silencers of dust control installation in mechanical coal processing plants

Place of the first implementation: KW S.A. Oddział KWK "Jankowice"

Field of action: sound absorbing-and-isolating shields

Field of action: sound absorbing-and-isolating shields

Project name: Shield of a coat of mine ventilation system’s main fan

Place of the first implementation: Przedsiębiorstwo Górnicze "Silesia"

Field of action: barriers of increased isolation power, silencers

Field of action: barriers of increased isolation power, silencers

Project name: Silencing the coal loading station

Place of the first implementation: KW S.A. Oddział KWK "Chwałowice"

Awards and prizes

2011

2011

Special distinction at the Concours-Lepine Fair (Paris 2011) - medal of the French Association of Inventors and Manufactures (AIFF) for "Low-noise emission objects ventilation system".

2010

Gold medal for the solution "System of fan acoustic shields" - POLEKO International Trade Fair of Environmental Protection.

Silver medal for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power" - World Exhibition on Innovation, Research and New Technologies Brussels Innova.

Silver medal for the innovative solution “System for damping the noise of fan for blast draught of power boiler” – International Warsaw Invention Show IWIS 2010.

Silver medal for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power" – iENA Nuremberg - International Trade Fair Ideas-Inventions-New Products.

Bronze medal for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power" - Concours-Lepine Fair (Paris 2010).

Diploma granted by the Minister of Science and Higher Education for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power".

Congratulation Letter of the Minister of Science and Higher Education for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power".

Mining Success of the Year 2010 in the category “Ecology” for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power".

2009

Gold medal with a distinction for the solution "Damper for WPWS-160 centrifugal fan" - POLEKO International Trade Fair of Environmental Protection.

Award in the Polish Competition for the Improvement of Work Conditions in the category “Technical and organizational solutions” for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power".

Gold medal with a distinction for the solution "Damper for intake hood and for exhaust hood for cooperation with fans of high power" – International Warsaw Invention Show IWIS 2009.

The Division of Applied Vibroacoustics is a supporting member of the Polish Acoustics Association.

The Division of Applied Vibroacoustics is a supporting member of the Polish Acoustics Association.

We invite you to collaboration.

Contact:

Marek Pierchała, Ph.D. Eng.

Manager of the Division of Applied Vibroacoustics

phone: +48 32 2374 347, +48 32 2374 644

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.; This email address is being protected from spambots. You need JavaScript enabled to view it.

Industrial partners:

Eurometal S.A.

Eurometal S.A.

Płochocińska 15, 03-191 Warszawa, Poland

http://www.eurometsa.pl

Field of collaboration: acoustic screens

Przedsiębiorstwo Usługowe Geocarbon sp. z o.o.

Przedsiębiorstwo Usługowe Geocarbon sp. z o.o.

Dunikowskiego 12-14, 40-127 Katowice, Poland

http://www.geocarbon.pl

Scope of collaboration: acoustic screens

Grama Sp. z o.o.

Grama Sp. z o.o.

Narutowicza 15, 41-503 Chorzów, Poland

http://www.grama.com.pl

Scope of collaboration: silencers, acoustic screens

World Acoustic Group S.A.

World Acoustic Group S.A.

Royal 1, 59-101 Polkowice, Poland

http://www.wagsa.eu

Scope of collaboration: acoustic screens

Field of action: acoustic screens in the environment - mixed, absorbing and reflecting screens

Field of action: acoustic screens in the environment - mixed, absorbing and reflecting screens Field of action: acoustic screens in the environment - reflecting screens

Field of action: acoustic screens in the environment - reflecting screens Field of action: acoustic screen with shutter panels

Field of action: acoustic screen with shutter panels Field of action: acoustic screens in closed spaces

Field of action: acoustic screens in closed spaces Field of action: silencers

Field of action: silencers Field of action: silencers

Field of action: silencers Field of action: silencers

Field of action: silencers Field of action: silencers

Field of action: silencers Field of action: sound absorbing-and-isolating shields

Field of action: sound absorbing-and-isolating shields Field of action: barriers of increased isolation power, silencers

Field of action: barriers of increased isolation power, silencers 2011

2011 The Division of Applied Vibroacoustics is a supporting member of the Polish Acoustics Association.

The Division of Applied Vibroacoustics is a supporting member of the Polish Acoustics Association. Eurometal S.A.

Eurometal S.A. Grama Sp. z o.o.

Grama Sp. z o.o. World Acoustic Group S.A.

World Acoustic Group S.A.

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych