We offer:

• designing of installations for processing of hard coal and other raw minerals,

• designing of machines and equipment for processing of coal and other raw minerals,

• designing of installations for management and treatment of wastes for recycling,

• testing the possibilities of manufacturing and use of alternative fuels,

• technological, laboratory and industrial tests,

• technological servicing of operated beneficiation machines and equipment.

Scope of activity:

Activities as regards mineral processing systems refer mainly to hard coal mining industry and mineral aggregates. The projects are realized within a full designing process together with laboratory tests and technological analysis.

The offer of the Division of Preparation Systems includes beneficiation, classification, crushing, dewatering, thickening, transportation and sampling processes.

Innovative solutions:

|

|

|

|

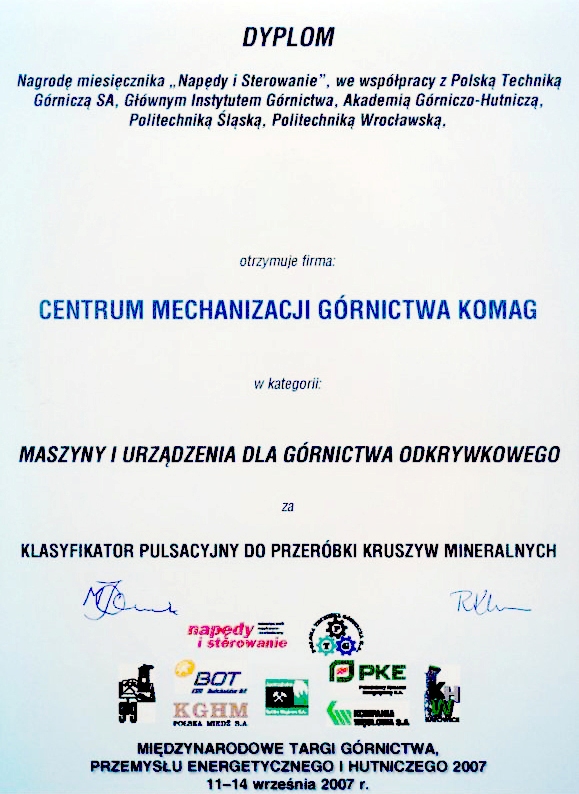

Pulsatory classifier is designed for separation of organic and mineral contaminants from natural aggregates, especially from gravel-and-sand feed of grain size 16(32)-2mm. Current design solutions of pulsatory classifier enable its installation and operation in a technological line of any plant producing aggregates. This classifier enables production of sand and gravel, which meet the requirements of quality standards and it enables adjustment of technological parameters of the products to the market demand. Innovative solution of electronic control system and pulsatory valve of a new generation used in a classifier enables:

• an adjustment of parameters of water pulsation cycle for changeable technological parameters of gravel-and-sand feed,

• automatic control of technological process,

• automatic operation.

In the result high effectiveness of separation of products as well as separation of organic and mineral contaminants has been obtained. A possibility of adaptation of the KOMAG classifier design to the requirements of each user as regards spatial conditions of the place of installation and expected efficiency and quality of trade products, what guarantees its high functionality, is an unquestionable advantage of this classifier.

The pulsatory classifier is the Polish device of the state-of-the-art solution that enables to obtain trade products meeting PN ISO requirements and market demands, which has a competitive price as regards similar devices of foreign manufacturers. The above-mentioned device for classification and purification of gravel-and-sand feeds would provide economic benefits in a result of differences in price of classified (washed) aggregate in relation to not-classified one.

Contact:

Piotr Matusiak, Ph.D. Eng.

Manager of the Division of Preparation Systems

phone: +48 32 2374474

mobile: +48 665660288

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych