|

|

Scope of tests includes:

|

KOMAG Institute of Mining Technology

MISSION

Innovative solutions for economy.

VISION

Design

Designing of machines and equipment

Tests

Laboratory of Applied Tests

Certification

Assessment of products' conformity

Projects

Projects realized by the KOMAG Institute from European Funds

- of components made of non-metallic materials, e.g.: parts of supports, conveyor belts, wedge belts, finished floors, varnishes, PVC fabrics, clothes, packaging and other electro-insulating materials

scope of the tests

- measurements of electrization of non-conducting materials with use of source of hogh voltage

- measurement of surface resistance, volume resistance and resistance between points

equipment for measurements and tests

- stand for electrization of non-conducting materials

- portable measuring apparati for testing the surface resistance, volume resistance and resistance between points

- of electric and electronic systems used in areas threatened by explosion hazard

measuring method

- experimental

scope of the tests

- tests of intrinsical safety of circuits in explosive mixtures, including: oxygen, hydrogen, methane, propane, ethylene, air.

equipment for measurements and tests

- spark gap, a system for gases dosage and a supply system make the testing stand

- of machines and equipment

- of electrical circuits at rated voltage up to 1kV

range of the tests

- tests as regards the measurements of resistance of electric systems insulations

- tests of dielectric strength of insulation to variable, constant and impact voltage

- measurements of resistance of contacts and electrical connections

- measurement of impedance parameters and RLC electric and electronic systems

- tests of warming-up the current circuits

|

|

|

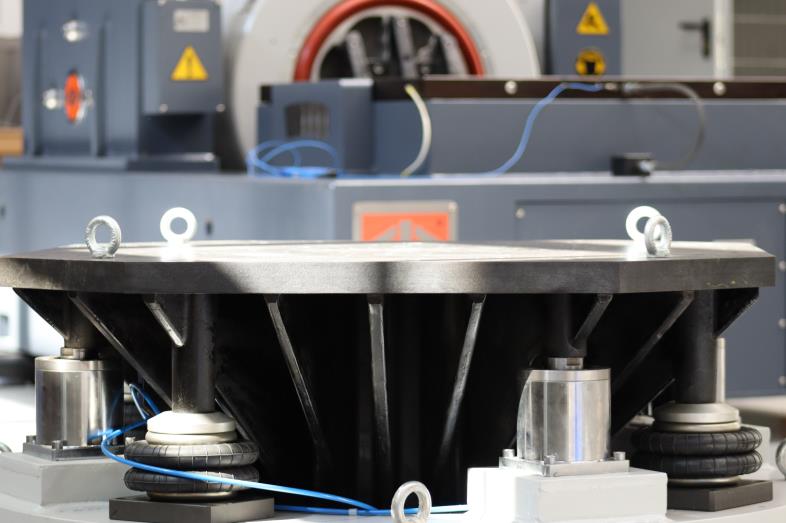

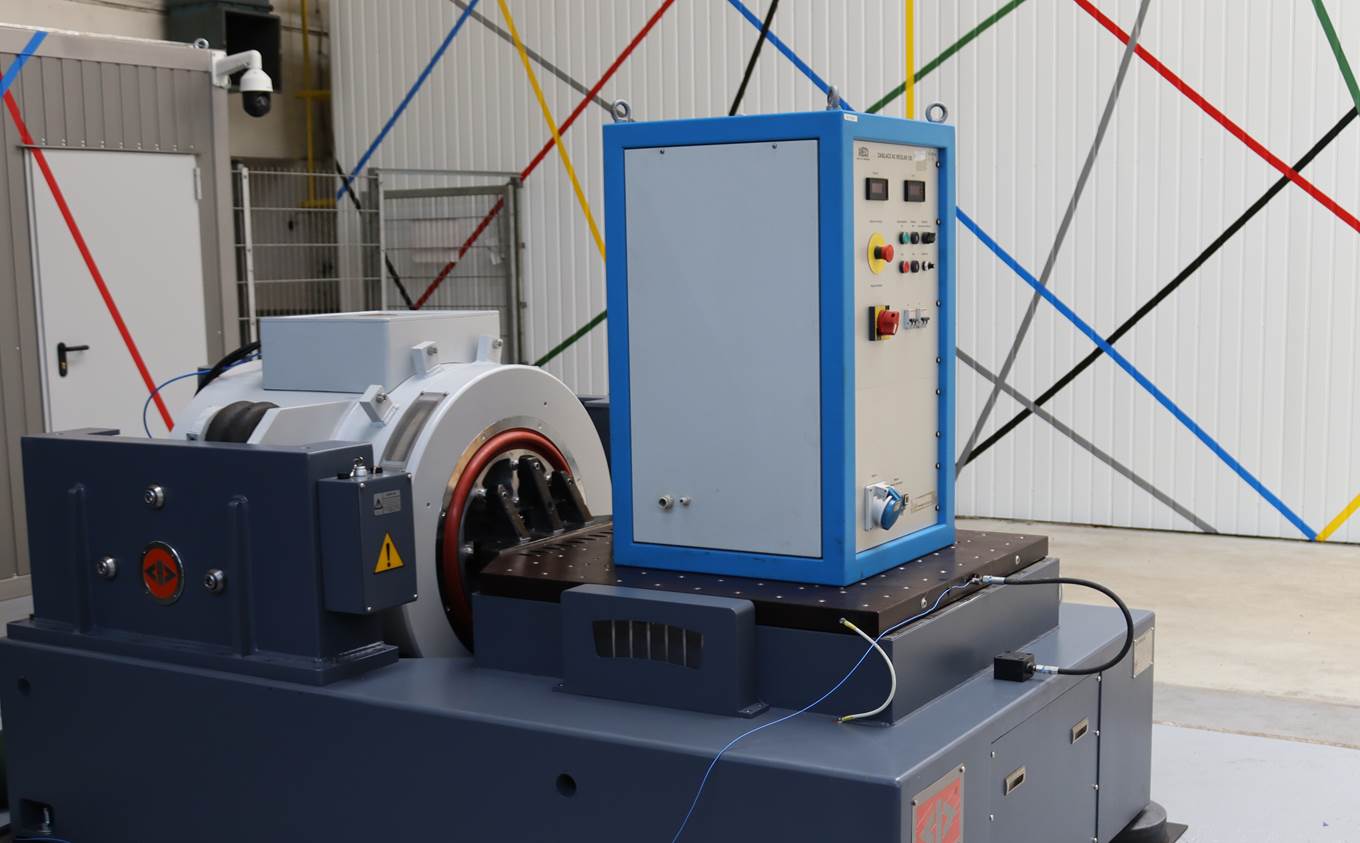

KOMAG Laboratory of Applied Tests extended its activity by vibration tests/exposures. Our testing equipment enables vibration tests in 3 perpendicular axes of objects weighing up to 900 kg. Exposures may take place in the following scope of parameters:

- Force: up to 70 kN (sinus, random),

- Force: up to 140 kN (shock),

- Frequency: (5-2000) Hz,

- Max acceleration: 900 m/s2,

- ax displacement: 75 mm p-p

The tests can be applied in scientific, experimental and engineering research work and for certification of new products or technologies. It is possible to test products according to standardized test procedures or the client's own testing methodologies. Examples of standardized testing methodologies are as follows:

- PN-EN 60068-2-27

- PN-EN 60068-2-64

- PN-EN 50125-3:2003 p.4.13

- PN-EN 61373

- PN-EN 60068-2-6

- MIL-STD 810F, Metoda 514.5, procedura I

- Norma NO-06-A107

- DO-160

- ETSI EN 300 019-X-X

- Regulamin nr 100 EKG ONZ

- UN 38.3

The tests can be used in the automotive, mechanical, aviation, railway, lighting, electric, space, transport, electromobility, military, medical, electronic, telecommunications, etc. industries. A wide range of applications enables testing the end products as well as machine and device subassemblies.

To diagnose damage or to gain knowledge about the tested product, high-speed video recording is also possible during the vibration tests, which will allow for a detailed analysis of the object's behavior during exposure to vibrations. A high-speed camera with the following parameters is used:

- Bandwidth 3 Gpx/s,

- Maximum resolution 1920 x 1080 pixels,

- Speed in full resolution 1 480 fps,

- Maximum speed is 94 695 fps (at a resolution of 640 x 8 pixels).

In addition, the following is tested:

- machines and equipment

- in working environment

according to the following standards:

- PN-N-01352,

- PN-N-01357,

- PN-N-01358,

- PN-EN ISO 5349-1, PN-EN ISO 5349-2,

- PN-EN ISO 28927-10,

- PN-EN 14253,

- PN-ISO 14695,

- PN-EN 60745-1, PN-EN 60745-2-3,

- vibration measurements by spectral and weighted methods in the 1/1; 1/3; 1/12; 1/24; 1/24 oct. bands,

- FFT analysis,

- time curves.

Contact:

Łukasz Orzech, Ph.D. Eng.

Manager of the Laboratory of Applied Tests

phone: +48 32 237 48 19

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.komag.eu/en

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych