Flexible scope of Laboratory accreditation includes the following tests:

- tests of mechanical and physical properties and flammability of toys for conformity with the requirements of 2009/48/EC Directive,

- tests of mechanical properties, durability and flammability of wheeled child conveyances,

- tests of mechanical and physical properties of changing units, playpens and children clothing,

- tests of migration of elements from children articles, including toys,

- tests of content of phthalates in children articles, including toys and products made of plastics,

- tests of presence as well as content of aromatic amines and azo dyes in children articles, including toys and textile products,

- tests of migration of monomers from children articles,

- tests of articles intended to come into contact with food as regards global and specific migration and formaldehyde content,

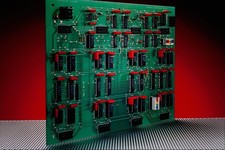

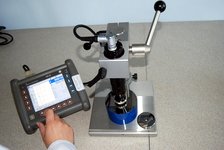

- tests of electrical and electronic equipment as regards the content of lead, cadmium, hexavalent chromium, mercury, polybrominated biphenyls (PBBs) and polybrominated diphenyl ethers (PBDEs),

- tests of textile and leather products as well as drying agents as regards the content of dimethyl fumarate,

- tests of packaging as regards the content of lead, cadmium, hexavalent chromium and mercury,

- tests of chemical composition of steel and iron cast products.

Within flexible scope of accreditation, the Laboratory has competences and accreditation as regards use and implementation of Laboratory own modified methods and updated standardized methods.

List of accredited tests within flexible scope of accreditation [PDF]

Contact:

Laboratory of Material Engineering and Environment

Manager: Beata Grynkiewicz-Bylina, Ph.D., Prof. at KOMAG

phone: +48 32 237 46 65

fax: +48 32 231 08 43

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

http://www.komag.eu

Act of 27th April 2001 “Environmental protection law” (OJ of 2001 No. 62 item 627 with amendments) obliges the manufacturers of electric and electronic equipment to limit an application of substances potentaially hazardous to the environment during the period of its use and after its disposal.

Act of 27th April 2001 “Environmental protection law” (OJ of 2001 No. 62 item 627 with amendments) obliges the manufacturers of electric and electronic equipment to limit an application of substances potentaially hazardous to the environment during the period of its use and after its disposal.

Badanie bezpieczeństwa wyrobów

Badanie bezpieczeństwa wyrobów Klaster Maszyn Górniczych

Klaster Maszyn Górniczych